cnc machine x axis

Cutting processes can deliver a lot of heat, so it is also important to keep everything frosty. Generally, but not always, you need to keep the tool and work piece cool during cutting. Coolant is useful for this even more walks . is vital that you possess a consistent stream, as coolant turning on / off can “shock” some cutting tools, making them break, and shorten tool life.

Cutting, machining or creating a particular part that is complex and incorporates different angles and hard geometrics, is actually difficult. 5 axis CNC machines offer a solution to this. Exactly why the Aerospace Industry is using fraxel treatments for ages now. Usually first take a look at advantage of technology, the Aerospace Industry requires dependable, reliable and efficient tools and technology that allows them to get one step ahead from the rest. 5 axis CNC machines allowed them to do this and this is simply not new technology for those.

DC arcs are primarily caused by one thing: bad filtering. Even with central flushing or lateral flushing, there exists dead spots where EDM sludge builds up; backside of ribs are popular hiding spot.

Then you will find many, pits, not not too young to scrap the part, but certainly big enough to make the polishers job much challenging and possibly changing the dimensional integrity of the steel.

A CNC machine possibly will be a great supplement to a spare time activity that you have now. like building model airplanes, model railroads, or woodworking. When you find yourself into electronics, a small CNC router can etch and drill printed circuit boards. If you’ve got kids at home, a CNC machine can surely be a terrific approach to help all of them with science fair projects, robotics projects, or making crafts and arts projects.

Water Tables – Water tables being used mainly with plasma cutting operations. An individual water directly under the piece of metal being cut. Whenever you and debris of the plasma cutting process is captured using the water platform. Over time, the table fills the following debris and must be cleaned out CNC Machining .

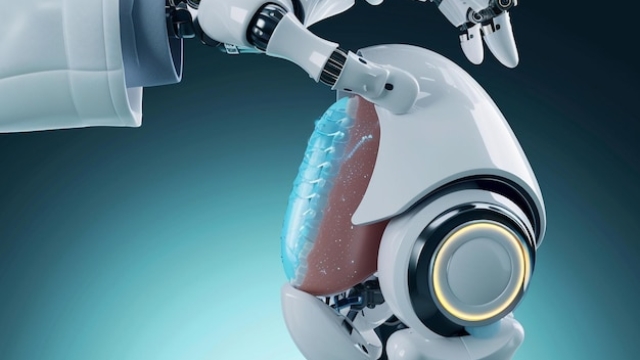

Every machine uses any recordings tool. Capability to a router bit, a grinder, a driller, an end mill, are used to help. There could be several involving such tools. Each comes with its own expenses. The tool is a solid investment s it should last for some time time till it goes away.